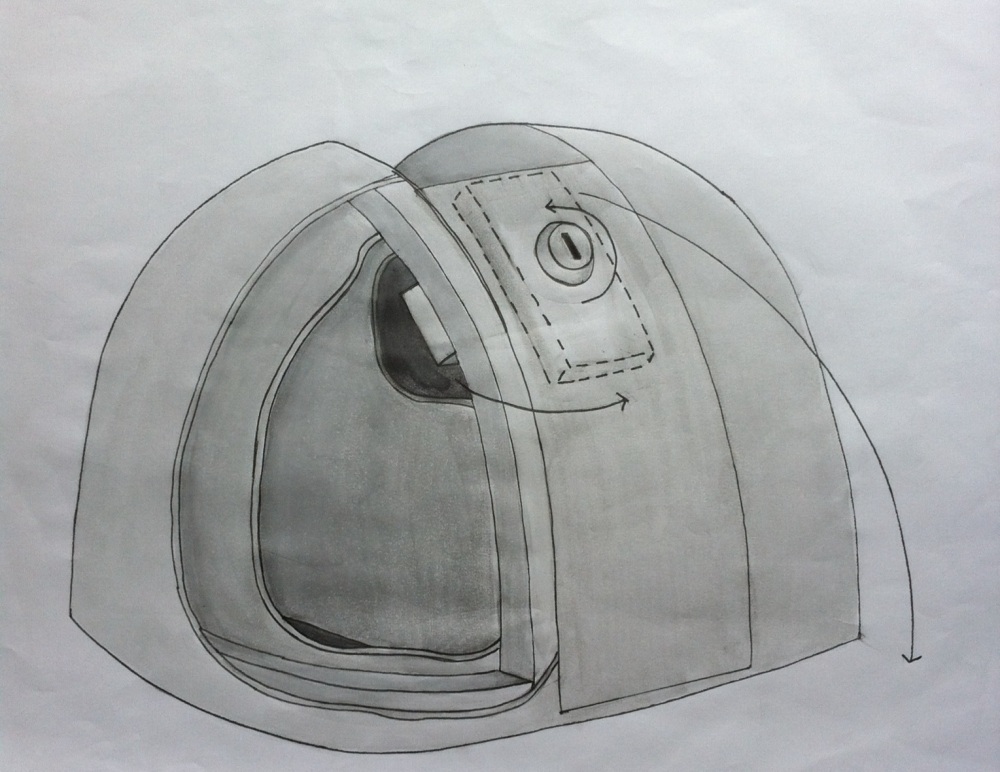

slush casting

slush casting is a variation of permanent moulding that uses urethane this process can be used to produce hollow casted parts, which is perfect for my product, because the shell on the out side needs to be hollow, the advantages of using urethane for this process are;

Wide Range of Hardness

The classification of hardness for polyurethane relies on the prepolymer’s molecular structure can be manufactured from 20 SHORE A to 85 SHORE D

High Load Bearing Capacity

Polyurethane has a high load capacity in both tension and compression. Polyurethane may undergo a change in shape under a heavy load, but will return to its original shape once the load is removed with little compression set in the material when designed properly for a given application.

Flexibility

Polyurethanes perform very well when used in high flex fatigue applications. Flexural properties can be isolated allowing for very good elongation and recovery properties.

Abrasion & Impact Resistance

For applications where severe wear prove challenging, polyurethanes are an ideal solution even at low temperatures.

Tear Resistance

Polyurethanes possess high tear resistance along with high tensile properties.

Resistance to Water, Oil & Grease

Polyurethane’s material properties will remain stable (with minimal swelling) in water / oil / grease. Polyether compounds will last many years in subsea applications.

Electrical Properties

Polyurethanes exhibit good electrical insulating properties.

Wide Resiliency Range

Resilience is generally a function of hardness. For shock-absorbing elastomer applications, low rebound compounds are usually used i.e. resilience range of 10-40%. For high frequency vibrations or where quick recovery is required, compounds in the 40-65% resilience are used. In general, toughness is enhanced by high resilience.

Strong Bonding Properties

Polyurethane bonds to a wide range of materials during the manufacturing process. These materials include other plastics, metals, and wood. This property makes polyurethane an ideal material for wheels, rollers, and inserts.

Performance in Harsh Environments

Polyurethane is very resistant to temperature extremes, meaning harsh environmental conditions and many chemicals will not cause material degradation.

Mold, Mildew & Fungus Resistance

Most polyether based polyurethanes do not support fungal / mold / mildew growth and are therefore highly suitable for tropical environments and FDA applications. Special additives can also be added to reduce this in polyester materials as well.

Color Ranges

Varying color pigments can be added to polyurethane in the manufacturing process. Ultraviolet shielding can be incorporated into the pigment to provide better color stability in outdoor applications.

Economical Manufacturing Process

Polyurethane is often used to manufacture one-off parts, prototypes or high volume, repeat production runs. Size ranges vary from a couple grams to 2000lb parts.

Short Production Lead Times

Compared to conventional thermoplastic materials polyurethane has a relatively short lead time with significantly more economical tooling costs.

information from ( http://www.precisionurethane.com/urethane-advantage.html ) and ( http://thelibraryofmanufacturing.com/slush_casting.html )